Discover the Advantages of Using a stretch wrapping machine for Effective Product Packaging Solutions

In the world of packaging remedies, effectiveness is key. Automation has actually produced significant improvements, such as the stretch wrapping machine. With its ability to cover things securely and rapidly making use of elastic plastic movie, it provides a high level of precision and speed. It's not almost covering items, however also regarding decreasing labor costs, minimizing waste, and keeping aesthetic allure. What makes these equipments a game-changer in the product packaging market?

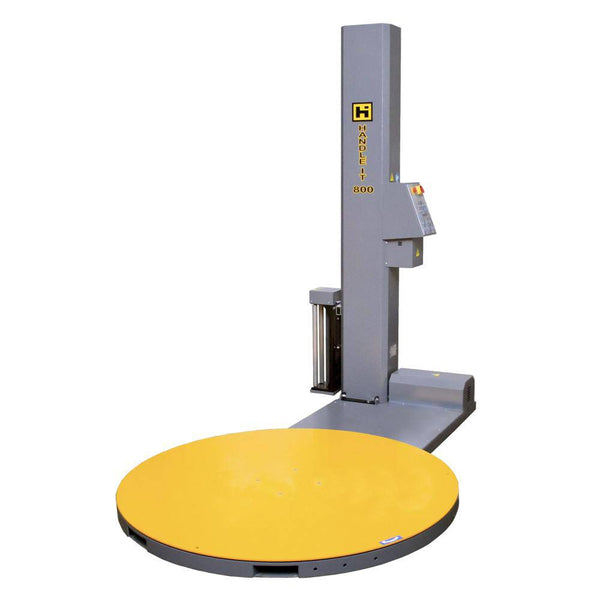

Recognizing the Functionality of Stretch Wrapping Machines

Originating the product packaging sector, stretch covering machines enhance the procedure of safely product packaging products for transportation or storage. These advanced equipments employ a straightforward yet effective system, making use of a stretchable plastic film that is covered around products, giving stability and defense. The products, often organized on a pallet, are turned as the movie is dispensed, guaranteeing a safe and secure and tight cover.

The film's elasticity offers a dual objective: it tightly binds the items together, decreasing the risk of damages because of motion, and it supplies an obstacle versus dirt, wetness, and various other potential damaging aspects. In addition, the clear nature of the stretch movie permits easy identification of the packaged items.

The makers differ in their procedure mode, with some being semi-automatic, requiring minimal human treatment, and others being completely automatic, qualified of individually taking care of the whole covering procedure. No matter their mode, stretch wrapping devices are a cornerstone of reliable and risk-free product packaging.

Exactly How Stretch Wrapping Machines Enhance Performance

Improving productivity degrees substantially, stretch wrapping equipments enhance the packaging procedure with their automated abilities. These sophisticated machines make it possible for business to cover a high volume of bundles swiftly and efficiently, supplying a consistent wrapping result that manual approaches simply can not match. This rate and consistency convert directly into raised performance, making it possible for services to meet requiring supply timetables and customer assumptions.

Furthermore, stretch wrapping makers call for marginal human treatment. As soon as the equipment is established and the covering specifications are set up, the maker can run separately, liberating workers to concentrate on various other important tasks. This automation not only reduces labor prices but likewise gets rid of human errors, ensuring the quality of covering stays consistent.

Furthermore, the usage of stretch wrapping devices commonly causes less downtime. stretch wrapping machine. With their robust layout and reliable operation, these devices are less prone to failures and upkeep concerns, making certain continuous process and boosted efficiency

Decreasing Material Waste With Stretch Covering Machines

While boosting productivity, stretch covering equipments also play a crucial role in minimizing product waste. The precision of these devices guarantees that each bundle is wrapped with the precise quantity of material needed, decreasing excess waste. This precision not just leads to an aesthetically pleasing and regular package, yet additionally contributes significantly to environmental sustainability.

Fundamentally, the utilization of stretch covering makers in a product packaging line is not only a step in the direction of reliable productivity, click resources but additionally explanation a jump in the direction of green practices by significantly decreasing product waste.

Price Reduction: A Secret Benefit of Stretch Covering Machines

In enhancement to mitigating product waste, one more considerable advantage of stretch covering machines is their capacity for price reduction. These devices are efficient, requiring much less hands-on labor for packaging goods, thereby minimizing labor prices.

Furthermore, stretch covering makers use less material to package goods safely as contrasted to traditional covering approaches. This efficient use products not only minimizes waste but likewise decreases expenditure on product packaging products.

The devices additionally decrease damages to products throughout transportation. With safe and secure and strong product packaging, the danger of item damages decreases, minimizing the expenses related to item returns and substitutes.

Lastly, the rate and effectiveness of stretch covering devices can enhance production prices. Faster packaging times suggest that companies can package and ship even more items in less time, enhancing overall productivity.

Applying Stretch Wrapping Machines in Your Packaging Process

Given the impressive benefits of stretch wrapping makers, incorporating them into your product packaging process can be a game-changing decision. The implementation procedure needs mindful preparation and training to ensure optimal use. An analysis of the existing product packaging process here are the findings is required to figure out the suitable maker type and dimension (stretch wrapping machine). The choice needs to line up with the package dimensions, weight, and the quantity of things to be wrapped daily.

Educating team on maker operation is important. This includes recognizing the equipment's capabilities, fixing typical issues, and sticking to safety and security standards. By doing so, companies can ensure a reliable, cost-efficient product packaging process, gaining the complete benefits of their financial investment in stretch covering machines.

Conclusion

In final thought, stretch wrapping machines offer reliable, cost-effective packaging remedies. These machines make sure item stability and security, while likewise supplying aesthetically pleasing bundles.

As soon as the machine is set up and the covering criteria are set up, the machine can operate independently, freeing up workers to concentrate on various other critical tasks.While improving efficiency, stretch covering makers additionally play a crucial role in decreasing material waste.Provided the excellent advantages of stretch covering makers, incorporating them right into your packaging procedure can be a game-changing choice - stretch wrapping machine. By doing so, services can ensure an effective, cost-effective packaging procedure, reaping the full advantages of their financial investment in stretch covering makers

In final thought, stretch wrapping devices supply efficient, cost-efficient packaging options.